In the world of manufacturing, innovation is the key to staying competitive and meeting the ever-evolving demands of the market. One technology that has been making waves and transforming the landscape is 3D printing. Also known as additive manufacturing, 3D printing has moved from being a futuristic concept to becoming a tangible reality, with significant implications for manufacturers and engineers.

The Evolution of 3D Printing

Early Beginnings

The journey of 3D printing began in the 1980s when Chuck Hull invented stereolithography, a process that allows for the creation of three-dimensional objects using digital data. This technology laid the foundation for subsequent advancements in additive manufacturing.

Technological Advancements

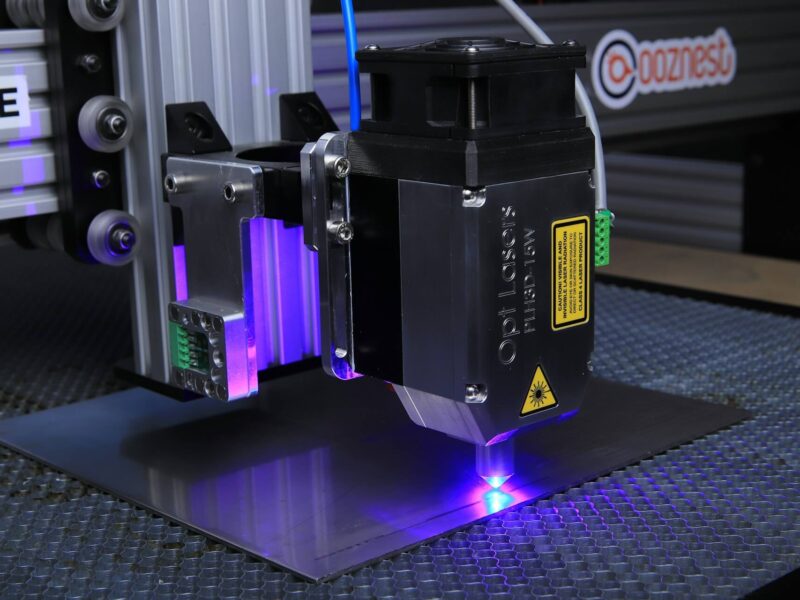

Over the years, 3D printing technology has evolved rapidly, thanks to continuous innovations in materials, processes, and software. Today, we have a variety of 3D printing methods available, including Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Direct Metal Laser Sintering (DMLS), each offering unique advantages for different applications.

3D printing stands to revolutionize the manufacturing industry by providing unprecedented levels of customization and efficiency. This technology allows manufacturers to create complex designs with accuracy and speed, reducing waste and streamlining production processes. For companies in the custom closet sector, 3D printing can enable tailored solutions that meet unique customer needs while minimizing lead times. With the ability to quickly prototype and produce intricate components, manufacturers can enhance their offerings and maintain a competitive edge. To explore how embracing 3D printing can transform your business, learn more about the solutions available for custom closet companies.

The Impact of 3D Printing on Manufacturing

Customization and Flexibility

One of the most significant advantages of 3D printing is its ability to produce customized products with high precision. Unlike traditional manufacturing methods, which often require expensive molds and tooling, 3D printing allows for the creation of complex geometries and intricate designs without additional costs. This flexibility is particularly beneficial for industries such as aerospace, automotive, and healthcare, where bespoke solutions are often required.

Rapid Prototyping

3D printing has revolutionized the prototyping phase of product development. Engineers can now quickly produce functional prototypes, test them, and make necessary adjustments in a fraction of the time it would take using traditional methods. This acceleration of the design cycle not only reduces time-to-market but also fosters innovation by enabling more iterations and experimentation.

Efficient Production Processes

Additive manufacturing streamlines production processes by reducing the need for multiple components and assembly steps. Complex parts that would traditionally require several separate pieces can be printed as a single unit, minimizing material waste and labor costs. Furthermore, 3D printing allows for on-demand production, which means manufacturers can produce parts as needed, reducing inventory costs and storage requirements.

Innovative Applications of 3D Printing

Aerospace Industry

In the aerospace sector, 3D printing is being used to create lightweight yet robust components that contribute to fuel efficiency and performance. Companies like Boeing and Airbus are leveraging additive manufacturing to produce parts that are not only lighter but also more durable, leading to significant cost savings and enhanced safety.

Automotive Industry

Automotive manufacturers are using 3D printing to produce everything from prototypes to end-use parts. For instance, General Motors has utilized additive manufacturing to create lightweight brackets and other components, resulting in improved vehicle performance and reduced emissions. Moreover, 3D printing enables the production of spare parts on demand, ensuring faster repairs and reduced downtime for vehicles.

Healthcare Industry

The healthcare sector has embraced 3D printing for its ability to produce patient-specific medical devices and implants. Custom prosthetics, dental implants, and even bioprinted tissues are now possible thanks to advancements in additive manufacturing. This personalized approach not only improves patient outcomes but also reduces the risk of complications.

The Future of 3D Printing in Manufacturing

Continuous Innovation

As 3D printing technology continues to evolve, we can expect further advancements in materials, speed, and precision. Researchers are exploring new materials, including metals, ceramics, and even biological tissues, opening up a world of possibilities for additive manufacturing.

Integration with Industry 4.0

The integration of 3D printing with Industry 4.0 technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, will further enhance its capabilities. Smart factories equipped with 3D printers will be able to produce highly customized products with unprecedented efficiency, driving the next wave of industrial revolution.

Sustainability

3D printing has the potential to significantly reduce the environmental impact of manufacturing. By minimizing material waste and enabling the use of recycled materials, additive manufacturing can contribute to more sustainable production practices. Additionally, the ability to produce parts locally reduces the need for transportation, further lowering the carbon footprint.

Conclusion

The power of 3D printing in the manufacturing industry is undeniable. Its ability to produce customized, complex parts with high precision and efficiency is transforming the way we design, prototype, and manufacture products. As the technology continues to advance, it will unlock new opportunities for innovation, sustainability, and competitiveness in the manufacturing sector.

For manufacturers and engineers looking to stay ahead of the curve, embracing 3D printing is not just an option—it’s a necessity. By leveraging the capabilities of additive manufacturing, businesses can drive growth, foster innovation, and deliver superior products to the market.

Are you ready to unlock the power of 3D printing in your manufacturing processes? Start exploring the possibilities today and position your business for success in the future!